Exploring Central Valves Innovations at the 2025 China Import and Export Fair

As the global market continues to evolve, the valve industry is witnessing significant advancements, particularly in the domain of Central Valves. According to a recent report by MarketsandMarkets, the global valve market is projected to reach USD 93.7 billion by 2025, growing at a CAGR of 5.5% from 2020 to 2025. This growth is driven by the increasing demand in sectors such as oil and gas, water and wastewater treatment, and energy generation. The 2025 China Import and Export Fair, also known as the 138th Canton Fair, serves as a pivotal platform for showcasing the latest innovations in Central Valves, which are critical for operational efficiency and safety in various industrial applications. Here, industry leaders will converge to explore cutting-edge technologies, discuss regulatory impacts, and demonstrate innovative solutions to enhance functionality and reliability in valve performance. This event not only highlights the growth potential of Central Valves but also underscores the importance of collaboration and knowledge exchange in addressing the challenges faced by the industry today.

Innovative Trends in Central Valve Technology Featured at the 2025 China Import and Export Fair

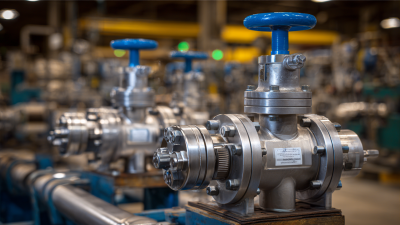

At the 2025 China Import and Export Fair, the spotlight is on the transformative innovations in central valve technology. This year, key trends showcase a shift towards automated systems and enhanced durability, driven by increased demand across industries such as oil and gas, water management, and manufacturing. According to a report by MarketsandMarkets, the global valve market is projected to grow from $70.2 billion in 2021 to $92.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.8%. Notably, central valves are at the forefront, with advancements in materials and design enabling better performance and longevity.

One of the standout innovations is the integration of IoT (Internet of Things) technology, allowing for real-time monitoring and predictive maintenance of valve systems. This shift not only minimizes downtime but also boosts operational efficiency significantly. As companies strive for sustainability, many are exploring the use of eco-friendly materials in valve production, aligning with global environmental standards. Reports suggest that nearly 30% of the market is now focusing on sustainable technologies, highlighting a critical trend in the industry.

**Tips**: When selecting central valves for your operations, consider opting for models that incorporate IoT features for enhanced monitoring and efficiency. Additionally, evaluate suppliers based on their commitment to sustainable practices to ensure compliance with future environmental regulations. Stay informed about the latest materials and designs to maximize the performance and lifespan of your valve systems.

Key Market Data and Projections for Central Valve Industry Growth Post-2025

The central valve industry is poised for significant growth in the coming years, with projections indicating a robust market trajectory. According to recent data from Business Research Industry, the global valve positioner market is expected to expand from USD 2.24 billion in 2025 to USD 2.79 billion by 2030, reflecting a compound annual growth rate (CAGR) of 4.4%. This growth signals a heightened demand for precision control in fluid handling systems, which is critical for various industrial applications.

Additionally, the thermostatic mixing valve market is anticipated to reach approximately USD 2.1 billion by 2035, driven by increasing applications in residential and commercial infrastructure. This sector is projected to experience a CAGR of 4.8% during the same forecast period. Innovations within the central valves domain, particularly in energy efficiency and automation, are expected to be pivotal in attracting investments and enhancing operational efficiencies across multiple industries. As manufacturers focus on integrating smart technologies, the landscape for central valves will undoubtedly evolve, catering to the dynamic needs of the market post-2025.

Central Valve Industry Growth Projections Post-2025

This chart illustrates the projected market growth of the central valve industry from 2025 to 2030. The data indicates a steady increase in market size, reflecting the anticipated innovations and demand in the central valve sector.

Sustainability Initiatives in Central Valve Manufacturing Presented at the Fair

At the 2025 China Import and Export Fair, the spotlight on sustainability initiatives in central valve manufacturing marked a significant shift in industry practices. A recent report by Markets and Markets highlights that the global valve market is projected to reach $87.1 billion by 2026, with an increasing emphasis on sustainable materials and processes accounting for a growing share of this market. This fair showcased several innovations aimed at reducing carbon footprints and enhancing the recyclability of products, reflecting the industry's response to environmental challenges.

Exhibitors demonstrated advanced technologies such as energy-efficient valve systems and the use of biodegradable materials in valve production. For instance, the adoption of eco-friendly coatings can decrease hazardous waste by up to 30%, aligning with the ISO 14001 environmental management standards. Furthermore, a study by Research and Markets indicates that integrating smart technologies into central valves can enhance efficiency and reduce energy consumption by 25% in industrial applications. These developments not only cater to regulatory demands but also appeal to an increasingly eco-conscious consumer base, underscoring the central valve sector's commitment to sustainable growth.

Impact of Smart Valve Solutions on Efficiency in Industrial Applications

At the 2025 China Import and Export Fair, innovations in central valves, particularly smart valve solutions, are set to revolutionize efficiency in industrial applications. These advanced technologies leverage IoT connectivity and automated controls, enabling real-time data monitoring and precise flow regulation. Industries ranging from oil and gas to water management stand to benefit significantly from the optimization offered by smart valves, leading to reduced operational costs and enhanced safety measures.

Tips: When considering the integration of smart valve solutions, businesses should assess their existing infrastructure and identify areas where automation can provide the most value. Engaging with expert vendors during exhibitions can also yield insights into the latest enhancements tailored for specific industrial needs.

Additionally, the introduction of smart valve technology promotes not only efficiency but also sustainability. By enabling precise control over fluid dynamics, companies can minimize waste and carbon footprints. Implementing smart sensors can help monitor energy consumption and streamline processes further, aligning with the global movement towards greener industrial practices.

Showcasing Leading Chinese Manufacturers and Their Innovations in Central Valves

The 2025 China Import and Export Fair promises to be a pivotal event for showcasing innovations in central valves, a critical component in various industrial applications. Leading Chinese manufacturers are gearing up to present their latest advancements that enhance efficiency, performance, and sustainability. According to a report by MarketsandMarkets, the global valve market is projected to grow from USD 75.05 billion in 2020 to USD 93.92 billion by 2025, with the Asia-Pacific region leading the charge due to rapid industrialization and urbanization.

At the fair, attendees can expect to see innovations such as smart valves equipped with IoT capabilities that allow for real-time monitoring and data analytics. These advancements not only improve operational efficiency but also help industries in predictive maintenance, ultimately reducing downtime and operational costs. A study by the International Society of Automation indicates that implementing smart valve technologies can lead to a reduction in maintenance costs by as much as 30%, further emphasizing the importance of these innovations in a competitive market. Leading manufacturers will also highlight advancements in materials and engineering that enhance durability and resistance to extreme conditions, catering to the diverse needs of sectors like oil and gas, water treatment, and manufacturing.

Related Posts

-

How to Optimize Fluid Flow Efficiency with Central Valves Based on Industry Standards

-

Maximize Your Global Reach with Central Valves at the Record Breaking 2025 Canton Fair

-

Understanding Industry Standards: How to Choose the Best Back Valve for Optimal Performance

-

Finding Top Suppliers for Best Valve Models with Industry Insights and Data

-

How to Select the Right Valve Control Valve for Your Industrial Application

-

Solutions for Efficient Hyd Control Valve Implementations