Why Choose Electric Ball Valves for Your Pipeline System?

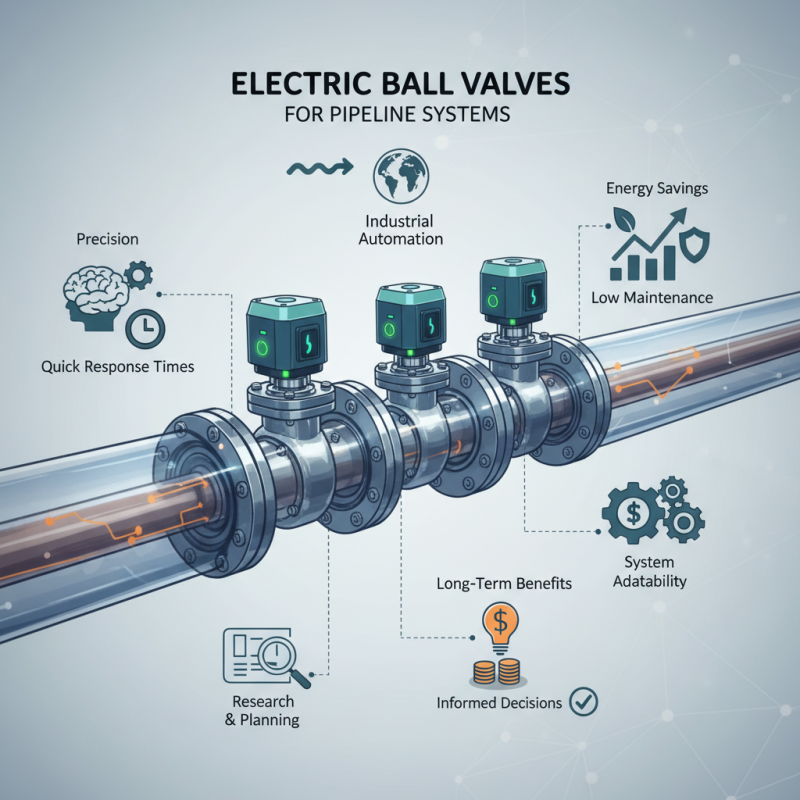

In the evolving world of industrial automation, the choice of valves is crucial for efficiency. Electric Ball Valves have emerged as a premier solution for pipeline systems. Renowned expert, Dr. Emily Carter, states, “Electric ball valves provide unmatched precision and reliability in flow control.” This highlights the significance of selecting the right valves for operational success.

These valves stand out due to their quick response times and low maintenance needs. For instance, their electronic actuator allows for seamless integration into automated processes. However, some may find the initial investment daunting. The long-term benefits often outweigh these concerns. Electric ball valves offer significant energy savings, improving overall operational efficiency.

Challenges do exist. One must consider compatibility with existing systems. Proper installation and maintenance are essential. Despite these challenges, the advantages of electric ball valves shine through. They enhance control and make systems more adaptable. With proper research and planning, organizations can make informed decisions and harness the benefits of electric ball valves effectively.

Benefits of Electric Ball Valves in Pipeline Systems

Electric ball valves offer significant advantages for pipeline systems. They provide precise control over fluid flow, allowing for better management of pressure and temperature. This control can enhance the efficiency of the entire system, leading to lower operational costs.

Installation is generally straightforward. Electric actuators simplify the process, minimizing the need for additional components. However, regular maintenance should not be overlooked. Without proper care, the actuators may face wear and tear, affecting performance. Consistent checks can prevent unexpected downtime.

In terms of safety, electric ball valves contribute to overall system reliability. They can quickly shut off flow in emergencies, which is crucial. Yet, if the power fails, the system must have a backup in place. This aspect is sometimes neglected. Planning for contingencies can provide peace of mind and reliability in critical operations.

Comparative Analysis: Electric vs. Manual Ball Valves

Electric ball valves offer distinct advantages over manual valves in pipeline systems. They provide precise control, reducing the risk of human error. Operators can easily adjust settings with the push of a button. This is especially beneficial in complex systems where accuracy is crucial. Manual valves, while reliable, require physical force and constant monitoring. Fatigue can lead to mistakes, resulting in leaks or inefficiencies.

Tips: Consider the layout of your pipeline. Electric valves can be installed in hard-to-reach areas without hassle. Ensure proper training for staff to maximize the effectiveness of electric controls.

Maintenance is another aspect to consider. Electric valves may require more initial investment but often save money long-term. They have fewer moving parts and can reduce repair frequency. Manual valves often encounter wear and tear from constant manual operation. Reflect on the long-term implications of both valve types on your operational costs.

Tips: Regularly check for software updates on electric valves. Keep an eye on battery backups to ensure reliability. Understanding your system's unique needs can lead to a more informed decision.

Key Features of Electric Ball Valves for Optimal Performance

Electric ball valves are a popular choice for modern pipeline systems. Their design allows for quick and precise control of fluid flow. One key feature is their ability to be operated remotely. This is especially useful in hard-to-reach places or hazardous environments. Operators can adjust the valves without physical presence, enhancing safety and efficiency.

Another advantage lies in their compact design. Electric ball valves take up less space than traditional valves. This is beneficial for installations with limited room. Additionally, they provide a tight seal, minimizing leaks. This tight sealing can lead to reduced energy costs, as systems operate more efficiently.

However, it's crucial to reflect on installation and maintenance considerations. Wiring can sometimes pose challenges. Proper training is essential for operators. If not handled correctly, performance may suffer. Regular checks and updates can help ensure optimal operation over time. It's vital to balance the benefits with these practical aspects.

Applications of Electric Ball Valves in Various Industries

Electric ball valves have gained popularity across various industries for their efficiency and reliability.

In the oil and gas sector, these valves provide precise control over fluid flow. They help manage pressure and temperature, crucial in refining and distribution processes. Many companies appreciate the automation electric ball valves offer. However, the initial installation cost can be high. Businesses must evaluate if the long-term benefits outweigh this expense.

In the water treatment industry, electric ball valves contribute significantly to operational efficiency. They simplify the flow control of chemicals during treatment. This automation reduces the risk of human error. Still, maintenance is vital. Neglecting regular checks can lead to failures, which may disrupt operations. Balancing reliability and upkeep is essential for success in this field.

Applications of Electric Ball Valves in Various Industries

Maintenance and Reliability of Electric Ball Valves in Pipelines

Electric ball valves have gained popularity due to their maintenance and reliability in pipeline systems. According to the TechSci Research report, the global electric valve market is expected to reach $8.03 billion by 2025, with a growing demand for automation. These valves offer precise control over fluid flow and require minimal maintenance compared to traditional valve types.

Regular maintenance still plays a crucial role. Electric ball valves often need periodic inspections to ensure the actuator is functioning properly. The seals and gaskets may degrade over time, requiring replacement to prevent leaks. An operational failure can lead to costly downtime, impacting productivity. Not all installations account for environmental factors like temperature fluctuations, which can affect performance.

Most electric ball valves are designed for long service life, but users must be mindful of their limitations. In high-pressure systems, the electric actuators may not perform as expected under fluctuating conditions. A study by Research and Markets highlights that 15% of pipeline failures are linked to valve-related issues. This statistic underscores the importance of choosing the right components and maintaining them regularly to enhance system reliability. The balance between automation and maintenance is essential for optimal performance.