The Ultimate Guide to Hydraulic T Valve Selection for Global Buyers in the Industrial Sector

In the ever-evolving landscape of the industrial sector, the selection of the right components is crucial for optimizing operational efficiency and ensuring seamless workflows. Among these components, the Hydraulic T Valve plays a pivotal role, facilitating the control and direction of fluid flow in hydraulic systems. According to a recent market analysis by MarketsandMarkets, the global hydraulic valve market is projected to reach USD 19.31 billion by 2025, growing at a CAGR of 5.31% from 2020. This growth underscores the increasing demand for reliable and efficient hydraulic solutions across various industries, including manufacturing, construction, and automotive. Selecting the appropriate Hydraulic T Valve not only enhances system performance but also significantly influences maintenance costs and operational longevity. In this ultimate guide, we will delve into the intricacies of Hydraulic T Valve selection, providing crucial insights to global buyers aiming to make informed decisions in this competitive market.

Key Factors to Consider When Selecting Hydraulic T Valves

When selecting hydraulic T valves, several key factors must be considered to ensure optimal performance and longevity in industrial applications. First, assess the specific requirements of your system, such as pressure ratings, flow rates, and fluid types. Understanding these parameters will help you choose a valve that meets your operational needs and guarantees safety.

Tip: Always refer to the manufacturer’s specifications and guidelines for operating conditions to prevent potential failures.

Next, examine the materials used in the valve construction. The choice of material can significantly impact the valve's durability and resistance to corrosion, which is crucial in demanding environments. Opt for materials that align with the fluids your system utilizes, as this can extend the lifespan of the valve and reduce maintenance costs.

Tip: Consider both the mechanical and chemical properties of the materials, and ensure they match your application requirements.

Finally, evaluate the installation and maintenance needs of the hydraulic T valve. Ease of installation can save time and labor costs, while straightforward maintenance procedures can enhance operational efficiency. Assess whether the valve is compatible with your existing system setup and how it can be serviced throughout its lifecycle.

Tip: Choose valves with accessible design features that simplify troubleshooting and repairs.

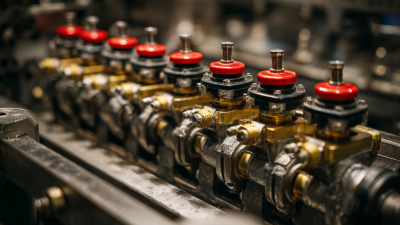

Types of Hydraulic T Valves: A Comparative Analysis

When it comes to hydraulic T valves, understanding the various types available in the market is crucial for buyers in the industrial sector. The most common types include ball valves, gate valves, and check valves. Each type offers distinct advantages depending on the specific application. For instance, ball valves are renowned for their durability and ability to provide a tight seal, making them ideal for on/off control in high-pressure systems. Meanwhile, gate valves excel in flow regulation, offering minimal obstruction, which is advantageous in large-scale operations.

Furthermore, check valves play a vital role in preventing backflow in hydraulic systems. Their automatic operation ensures that fluid flows in only one direction, aiding in the protection of equipment and maintaining system integrity. Buyers must also consider factors such as material construction—commonly brass, stainless steel, or plastic—as these influence the valve's longevity and compatibility with different fluids. By conducting a thorough comparative analysis of these types, industrial buyers can make informed decisions that best suit their operational needs, ultimately enhancing the performance and reliability of their hydraulic systems.

Evaluating Performance Metrics for Industrial Hydraulic T Valves

When selecting hydraulic T valves for industrial applications, evaluating performance metrics is paramount for ensuring optimal operation and longevity. Key metrics include flow rate, pressure drop, and valve response time. According to the International Fluid Power Society, a valve's flow rate should align with the specific demands of the system it operates within, as a mismatch can lead to inefficiencies or catastrophic failures. For instance, a flow rate exceeding 100 gallons per minute (GPM) is typical in heavy industrial applications, yet finer control may be necessary for precision tasks, necessitating careful consideration during selection.

Another critical performance metric is the pressure drop across the valve. Industry standards suggest that keeping pressure drops to less than 5-10% of the system pressure is ideal to maintain efficiency. Reports show that valves with a well-designed internal geometry can achieve lower pressure drops, improving overall system efficiency. Moreover, the response time of the valve, which affects how quickly it can open or close, is essential for automation processes. Data from the Hydraulic Institute indicates that a response time of less than 0.5 seconds can enhance system performance, particularly in dynamic systems requiring rapid adjustments. By focusing on these performance metrics, global buyers can make informed decisions that enhance their industrial operations.

Cost Considerations: Budgeting for Hydraulic T Valve Purchases

When budgeting for hydraulic T valve purchases, it’s crucial to understand the various cost factors involved. According to a report from the International Journal of Fluid Power, the average price for hydraulic T valves can range from $50 to over $500, depending on the size, material, and pressure rating. Buyers must also consider additional expenses such as shipping, installation, and maintenance costs. For instance, while a cheaper valve might seem appealing upfront, investing in a higher-quality valve can lead to lower maintenance costs in the long run.

Tip: Always account for the total cost of ownership, which includes not just the initial purchase price but also ongoing operational costs. A study by the Fluid Power Institute highlighted that businesses often underestimate expenses related to valve replacements and repairs, which can double their anticipated budget for hydraulic systems.

Moreover, it’s vital to conduct thorough market research to find reliable suppliers. The Global Industrial Market Report indicates a significant variation in pricing among manufacturers, with some offering bulk purchase discounts. This trend underscores the importance of contract negotiation to achieve favorable terms and potentially lower costs. By aligning your budget with projected usage and performance needs, you can optimize your hydraulic T valve selection while maintaining cost efficiency.

Supplier Reliability: Choosing the Right Vendor for Global Procurement

When it comes to global procurement of hydraulic T valves, selecting a reliable supplier is paramount. The performance and longevity of hydraulic systems greatly depend on the quality of the valves used, making the vendor selection process critical. Buyers should prioritize suppliers with a proven track record in the industry, as this often correlates with the quality of their products and services. It is beneficial to evaluate the supplier's experience, customer feedback, and adherence to industry standards to ensure that they can meet your specific requirements.

In addition, communication is key when dealing with global manufacturers. Establishing a strong relationship with your supplier can streamline the procurement process and resolve any potential issues more efficiently. Look for vendors who are transparent about their production processes, lead times, and delivery schedules. Regular updates and clear communication help in building trust, ensuring that you can rely on them for not just initial orders but for long-term partnerships. Ultimately, an informed choice of supplier can significantly impact the success of your industrial operations.

Related Posts

-

10 Best Elevator Valve Solutions for Global Buyers in 2023

-

Ultimate Checklist for Choosing the Right Automatic Valves for Your Industrial Needs

-

Evaluating Automated Valves: A Comparative Analysis of Performance Metrics and Efficiency in Industrial Applications

-

5 Reasons Why Our Best Elevator Valve Outperforms Competitors by 35% in Efficiency

-

Unlocking the Advantages of Superior Air Control Valves for Enhanced Performance

-

Understanding the Different Types of Control Valves: A Comprehensive Guide