Understanding Import Export Certifications for Best Pressure Valves with a Step by Step Guide

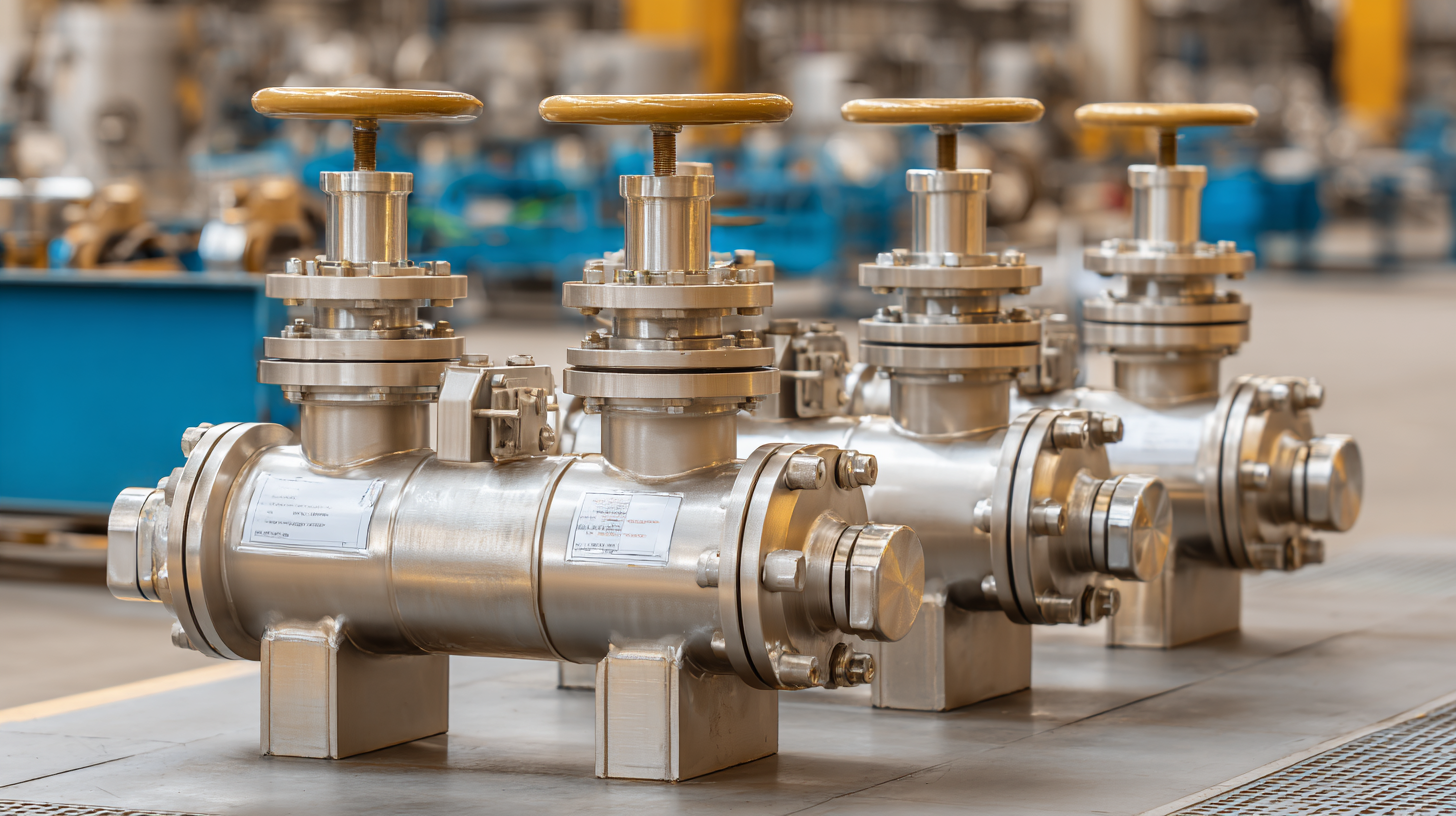

In the ever-evolving landscape of international trade, understanding import-export certifications is crucial, especially for specialized components like pressure valves. These essential devices, employed across various industries to control the flow and pressure of fluids, demand not just high quality but also compliance with a myriad of regulations and standards. As the global market continues to expand, so too does the importance of ensuring that pressure valves meet specific certifications for successful cross-border transactions.

This blog will provide a comprehensive step-by-step guide to navigating the complexities of import-export certifications, equipping manufacturers, suppliers, and engineers with the necessary knowledge to ensure their products align with market requirements. With the right certifications, professionals can enhance their competitiveness while ensuring safety and reliability in their pressure valve applications.

The Importance of Certifications in Importing and Exporting Pressure Valves

When engaging in the import and export of pressure valves, understanding certifications is crucial for ensuring compliance with international standards. Certifications serve as a testament to the quality and reliability of the valves being traded. They indicate that the products have been tested and meet necessary safety and performance criteria established by regulatory bodies. This helps prevent legal issues and costly recalls, as well as building trust with customers, who are more likely to choose products that come with verified certifications.

Furthermore, certifications can significantly impact market access. Many countries have strict regulations regarding the importation of industrial components, including pressure valves. Without the appropriate certifications, products may be denied entry, leading to delays and financial losses. By obtaining the necessary certifications, importers and exporters not only ensure smoother transactions but also gain a competitive edge in the global market. This commitment to maintaining high standards reflects well on their brand reputation and elevates customer confidence, ultimately contributing to long-term success in the industry.

Understanding Import Export Certifications for Best Pressure Valves

| Certification Type | Issuing Authority | Relevant Standards | Validity Period | Key Requirements |

|---|---|---|---|---|

| ISO 9001 | International Organization for Standardization | Quality Management Systems | 3 years | Documented processes, management commitment |

| CE Marking | European Union | Product Safety Standards | N/A | Compliance with EU legislation |

| ANSI/ISA 12.12.01 | American National Standards Institute | Instrumentation Standards | 5 years | Design, testing, and production requirements |

| ASME Certification | American Society of Mechanical Engineers | Boiler and Pressure Vessel Codes | 3 years | Quality control, inspection reports |

| ATEX Certification | European Committee for Electrotechnical Standardization | Equipment for Explosive Atmospheres | 5 years | Risk assessment, compliance with directive |

Key Industry Standards and Regulatory Requirements for Pressure Valves

When dealing with pressure valves, understanding industry standards and regulatory requirements is crucial for ensuring safety and performance. The primary standards governing pressure valves often include ASME, API, and ISO certifications. Compliance with these standards not only guarantees that the valves can withstand designated pressure levels but also ensures they meet specific operational criteria vital for various industrial applications. Familiarizing yourself with these regulations is essential for manufacturers looking to enter global markets, as many regions require compliance with their local standards before importation.

In addition to global standards, regional regulations play a significant role in the certification process. For example, the European Union has its own set of directives, such as the Pressure Equipment Directive (PED), which mandates rigorous testing and documentation for valves intended for use within its member countries. Similarly, in the United States, adherence to the National Board Inspection Code (NBIC) is necessary for the safe operation of pressure equipment. Understanding these requirements and obtaining the necessary certifications can significantly enhance the reliability and marketability of pressure valves, ultimately contributing to safer industrial operations worldwide.

A Comprehensive Step-by-Step Guide to Obtaining Certification for Pressure Valves

When it comes to ensuring the quality and safety of pressure valves, obtaining the necessary certifications is crucial. The process can seem daunting, but with a comprehensive step-by-step guide, manufacturers can navigate through the requirements with ease. The first step typically involves understanding the specific certifications applicable to the type of pressure valve being produced. Different markets may have unique regulations, so it's essential to research standards such as ASME, ISO, or API, depending on the intended application and region.

Once the relevant standards are identified, the next step is to engage with a recognized certification body. This partnership can guide manufacturers through the testing and inspection processes necessary for certification. Gathering documentation, such as design specifications and material safety data sheets, is vital. Following this, conducting the necessary tests to evaluate the performance and safety of the valves will be pivotal in demonstrating compliance. With the successful completion of testing, manufacturers can then compile and submit all required documentation to the certifying authority, paving the way for successful certification and ultimately, market acceptance.

Pressure Valve Certifications by Type

This chart represents the number of different types of import export certifications obtained for pressure valves across various categories. The data shows the popularity and necessity of certifications for quality assurance in the industry.

Emerging Technologies in Pressure Valve Manufacturing and Their Certification Needs

In the rapidly evolving field of pressure valve manufacturing, emerging technologies are redefining industry standards and creating new certification requirements. Advanced materials, such as high-performance polymers and additive manufacturing techniques, allow for the production of valves that are lighter, more durable, and resistant to extreme temperatures and pressures. These innovations demand corresponding adjustments in certification protocols to ensure that products meet safety and performance benchmarks.

As manufacturers adopt smart technologies, including IoT-enabled devices, the complexity of certification grows. These pressure valves not only require traditional mechanical testing but also necessitate compliance with cybersecurity and data protection standards. Industries must stay updated on regulatory shifts and ensure that their certification processes incorporate tests for these new functionalities. Embracing these changes is essential for manufacturers aiming to maintain competitiveness in a market that increasingly prioritizes advanced technology alongside reliability.

Market Outlook: Growth and Trends in the Pressure Valve Industry for 2025

The pressure valve industry is poised for significant growth, with forecasts indicating a compound annual growth rate (CAGR) of approximately 6.5% from 2022 to 2025. Driven by technological advancements and increasing demand in sectors such as oil and gas, water treatment, and manufacturing, investment in pressure valve systems is expected to soar. As industries prioritize safety and efficiency, the demand for high-performance valves that meet stringent regulatory standards will grow, shaping the market outlook for years to come.

Tips: When considering pressure valve certifications, always ensure that the products comply with ISO standards and other relevant certifications specific to your industry. This not only guarantees quality but also improves market competitiveness.

As we look toward 2025, sustainability trends are reshaping the pressure valve sector. The growing emphasis on reducing carbon footprints is compelling manufacturers to innovate eco-friendly designs and materials. Additionally, the adoption of smart technology, such as IoT-enabled pressure valves, is on the rise, resulting in improved monitoring and predictive maintenance capabilities.

Tips: Stay ahead of the curve by investing in training for your team regarding new technologies and compliance requirements, ensuring your organization remains competitive in this rapidly evolving market.