Mastering the Selection Process for Best Hydraulic Pressure Valves in Global Sourcing

In the rapidly evolving landscape of industrial automation and fluid control, mastering the selection process for hydraulic pressure valves has become crucial for maximizing efficiency and reliability in global sourcing strategies. According to a recent report by Markets and Markets, the global market for hydraulic valves is projected to reach USD 12.47 billion by 2025, growing at a CAGR of 4.2% from 2020. This growth reflects the increasing demand for advanced hydraulic systems across various sectors, including manufacturing, construction, and automotive industries. As organizations prioritize cost-effective and sustainable sourcing, understanding the intricacies of hydraulic pressure valves—ranging from design specifications to supplier capabilities—becomes paramount. This guide aims to equip industry professionals with the essential knowledge and best practices to navigate the selection process effectively, ensuring optimal performance and long-term value in their operations.

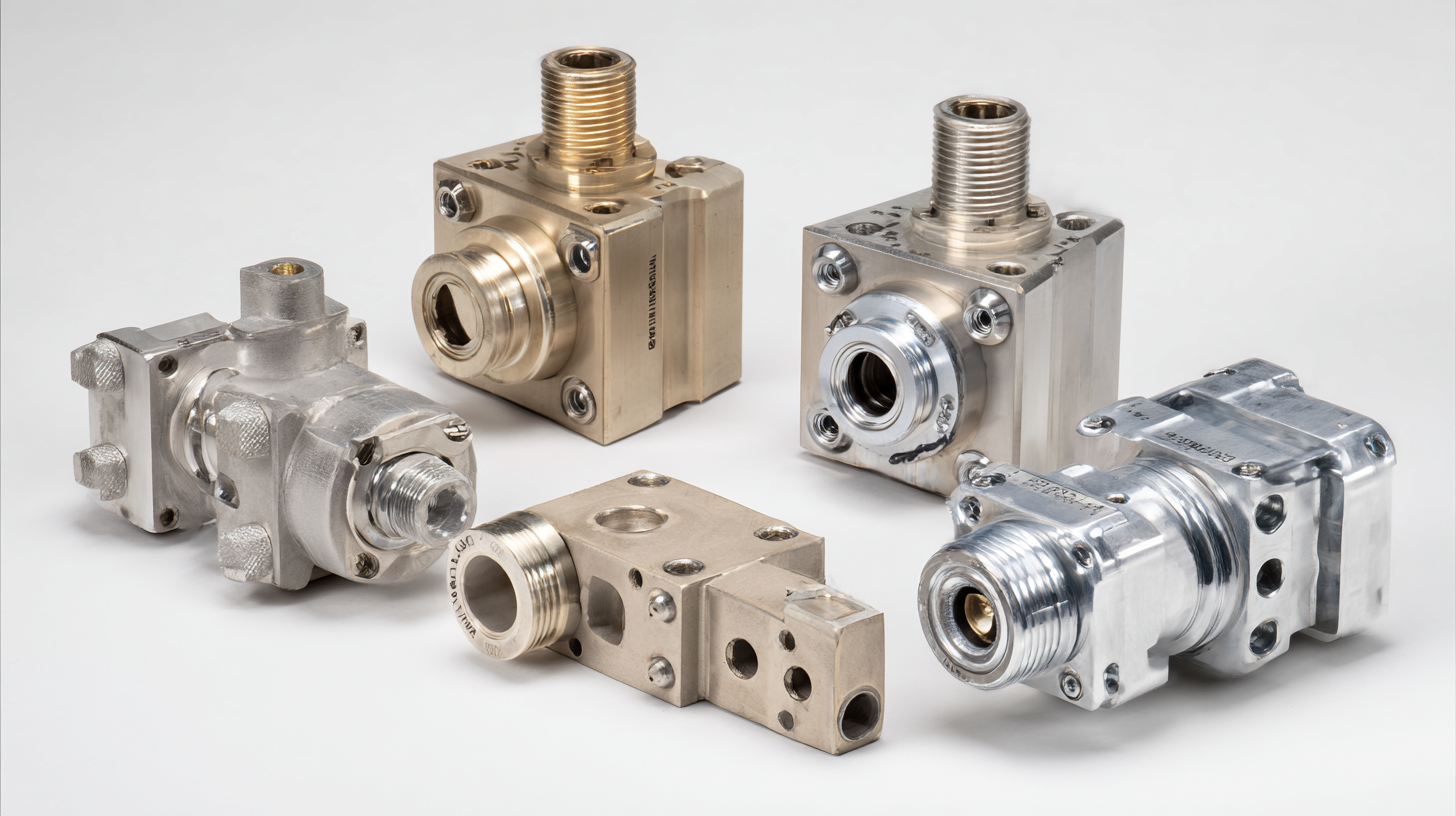

Importance of Selecting the Right Hydraulic Pressure Valves for Industrial Applications

Selecting the right hydraulic pressure valves is crucial for enhancing efficiency and reliability in various industrial applications. According to the International Organization for Standardization (ISO), improper selection of hydraulic components leads to a staggering 25% increase in operational downtime. This emphasizes the significance of choosing valves that are not only compatible with the specific hydraulic system but also capable of withstanding the operational pressures and environmental conditions encountered in the field.

Moreover, a report from MarketsandMarkets indicates that the global hydraulic valves market is expected to reach USD 4.6 billion by 2025, driven by increased industrial automation and the need for energy-efficient solutions. As industries prioritize sustainability, selecting hydraulic pressure valves with lower leakage rates and better flow control can substantially reduce energy consumption, thereby aligning with both economic and environmental goals. In this context, organizations must focus on sourcing valves from reputable manufacturers who adhere to international quality standards and innovative practices, ensuring long-term performance and value.

Mastering the Selection Process for Best Hydraulic Pressure Valves in Global Sourcing

| Valve Type | Maximum Pressure (PSI) | Flow Rate (GPM) | Material | Temperature Range (°F) | Applications |

|---|---|---|---|---|---|

| Direct Acting Relief Valve | 3000 | 20 | Steel | -40 to 250 | Industrial Machinery |

| Pressure Control Valve | 2500 | 15 | Aluminum | -10 to 220 | Construction Equipment |

| Flow Control Valve | 2000 | 25 | Brass | -20 to 180 | Automotive |

| Locking Valve | 1500 | 10 | Stainless Steel | -40 to 300 | Mobile Equipment |

| Pilot Operated Valve | 3500 | 30 | Cast Iron | -40 to 250 | Hydraulic Press |

Common Challenges in Sourcing Hydraulic Pressure Valves for Global Markets

Sourcing hydraulic pressure valves for global markets presents several challenges that can hinder a smooth procurement process. One common issue is navigating the diverse regulatory standards across different countries. Each region may have specific certifications and testing requirements, making it essential to stay informed about the legal landscape. Failure to comply can lead to delays and increased costs, potentially disrupting supply chains.

Tips: To mitigate these risks, establish a robust compliance checklist tailored to the regions you are sourcing from. Collaborate with local experts who understand the nuances of the regulatory environment to ensure all products meet necessary standards before procurement begins.

Another significant challenge is managing supplier relationships. With a wide array of suppliers available, ensuring quality while also negotiating competitive pricing can be a delicate balance. Poor supplier performance can result in inconsistent product quality and long lead times.

Tips: Develop strong partnerships by communicating your expectations clearly and monitoring performance metrics closely. Consider diversifying your supplier base to reduce dependency on a single source, allowing for better negotiation power and ensuring consistent supply.

Case Studies: Successful Implementations of Hydraulic Pressure Valves in Various Industries

In various industries, effective management of hydraulic pressure valves is crucial for optimizing performance and reliability. A recent case study highlights the success of implementing hydraulic pressure valves in self-cleaning water distribution networks (WDNs). The study leverages advanced algorithms to control diurnal flow velocities, thus maximizing self-cleaning capacities. This innovative approach has been shown to improve asset longevity and lower maintenance costs significantly within municipal water systems.

Moreover, the transition from traditional load sensing systems to digital hydraulics in excavators demonstrates the versatility and efficiency of modern hydraulic pressure valves in heavy machinery. This conversion not only enhances operational efficiency but also facilitates real-time control mechanisms, crucial for adapting to dynamic operational conditions. As industries increasingly prioritize smart technology solutions, the integration of hydraulic pressure valves will continue to play a pivotal role in enhancing system performance and reliability across various sectors.

Key Criteria for Evaluating Hydraulic Pressure Valve Suppliers Globally

When sourcing hydraulic pressure valves globally, evaluating suppliers with a discerning eye is crucial. One key criterion is the supplier's adherence to industry standards and certifications. Suppliers who comply with international quality benchmarks demonstrate their commitment to excellence and safety. It's essential to verify their ISO certifications or any specific certifications relevant to hydraulic systems to ensure reliability and performance.

Another important aspect is the supplier's manufacturing capabilities. Assessing the technology and processes they use can provide insights into their ability to meet your specific requirements. Consider their production capacity, flexibility in design, and whether they employ advanced manufacturing techniques. Additionally, evaluate their past projects and client feedback to gauge their reputation in the industry. A supplier that consistently delivers high-quality products and maintains open communication will be a valuable partner in your global sourcing efforts.

Evaluating Key Criteria for Hydraulic Pressure Valve Suppliers

Mitigating Risks in the Selection Process of Hydraulic Pressure Valves

When it comes to global sourcing of hydraulic pressure valves, mitigating risks during the selection process is paramount. The hydraulic valve market is projected to grow at a CAGR of 5.2%, reaching a market size of approximately $14 billion by 2024. This growth highlights the importance of meticulous selection criteria, focusing on quality, supplier reliability, and compliance with international standards. Ensuring that suppliers adhere to these standards not only minimizes operational risks but also enhances product performance and safety.

Moreover, the complexity of sourcing globally exacerbates potential challenges, including supply chain disruptions and quality discrepancies. A recent report by the International Society for Automation indicates that about 30% of organizations have experienced significant supply chain risks due to poor supplier performance. To navigate these issues, it is essential to implement a robust supplier evaluation framework that includes thorough audits, performance tracking, and a contingency plan for supplier failures. By prioritizing these strategies, organizations can effectively mitigate risks associated with the selection process of hydraulic pressure valves, ultimately leading to more resilient and efficient operations.