How to Optimize Fluid Flow Efficiency with Central Valves Based on Industry Standards

Optimizing fluid flow efficiency is critical in various industrial applications, particularly when employing central valves designed to meet stringent industry standards. According to a recent report by the International Society of Automation (ISA), improper valve selection can lead to a staggering 20% increase in operational costs due to inefficient fluid management.

Central valves play a pivotal role in regulating flow rates, ensuring that systems operate within optimal parameters. As fluid dynamics continue to evolve, adherence to industry standards becomes paramount; a study by the American Society of Mechanical Engineers (ASME) emphasized that systems equipped with high-performance central valves exhibit up to 30% improvement in overall efficiency compared to conventional alternatives.

Thus, understanding how to effectively optimize the use of central valves is essential for enhancing system performance, reducing energy consumption, and ensuring compliance with industry regulations.

Central valves play a pivotal role in regulating flow rates, ensuring that systems operate within optimal parameters. As fluid dynamics continue to evolve, adherence to industry standards becomes paramount; a study by the American Society of Mechanical Engineers (ASME) emphasized that systems equipped with high-performance central valves exhibit up to 30% improvement in overall efficiency compared to conventional alternatives.

Thus, understanding how to effectively optimize the use of central valves is essential for enhancing system performance, reducing energy consumption, and ensuring compliance with industry regulations.

Understanding Central Valves: Key Types and Their Role in Fluid Flow Optimization

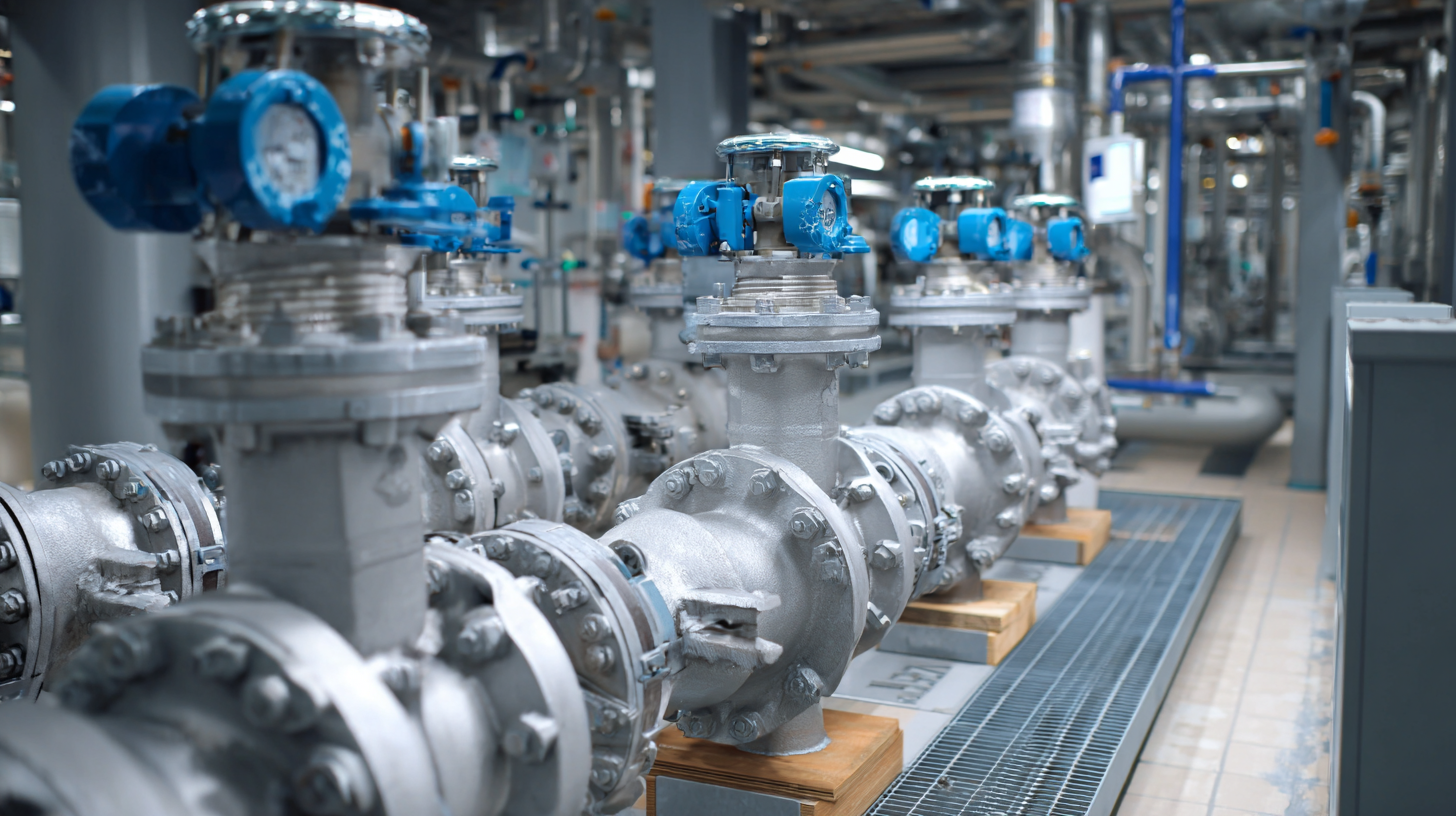

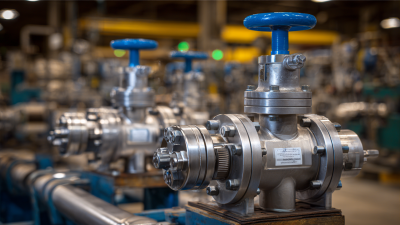

Central valves play a crucial role in optimizing fluid flow efficiency across various industries, from oil and gas to water treatment. There are several key types of central valves, including gate valves, globe valves, ball valves, and butterfly valves, each serving distinct functions. According to a report by Grand View Research, the global valve market is expected to reach USD 103.4 billion by 2025, driven largely by the increasing demand for fluid control solutions in industrial applications. Using the right type of central valve can significantly reduce pressure drops and enhance overall flow rates.

Understanding the characteristics of each valve type is essential for optimizing system performance. For instance, ball valves offer minimal resistance to flow, making them ideal for applications requiring quick shut-off, whereas globe valves provide better throttling capabilities, albeit with higher pressure loss. The selection of the appropriate valve based on industry standards can lead to improvements in energy efficiency. A study by the American Society of Mechanical Engineers (ASME) indicates that properly designed valve systems can enhance energy efficiency by up to 25%, highlighting the importance of central valves in fluid dynamics and their impact on operational costs and sustainability.

Analyzing Industry Standards: Pressure Drop and Flow Coefficient Metrics for Central Valves

In optimizing fluid flow efficiency, understanding

pressure drop and

flow coefficient metrics for central valves is crucial.

Pressure drop refers to the difference in pressure between the upstream and downstream ends of the valve, which can significantly impact overall system performance. A higher pressure drop can indicate excessive resistance and energy loss within the system, leading to increased operational costs. By adhering to industry standards for pressure drop, engineers can better design systems that avoid unnecessary energy expenditures and ensure smooth fluid dynamics.

Flow coefficient, or Cv, is another vital metric that quantifies the valve's ability to allow fluid flow. It is essential for determining the appropriate size and type of valve for specific applications. A higher Cv indicates a valve can handle a larger flow rate with less pressure drop, making it a preferred choice for efficient systems. By leveraging these metrics in design and selection processes, professionals can align their equipment with industry standards, ensuring optimal performance and reliability while minimizing waste and inefficiencies in fluid transport systems.

Implementing Advanced Control Techniques: Enhancing Flow Rate Efficiency with Smart Valves

The implementation of advanced control techniques plays a critical role in enhancing flow rate efficiency with smart valves. Recent advancements in valve technology are characterized by the integration of artificial intelligence (AI) and predictive control strategies, which significantly improve operational efficiency in various sectors. For instance, predictive control methods have been widely studied, with over 245 studies reviewed on HVAC systems alone, suggesting a growing inclination towards automation and optimization in fluid dynamics applications. By leveraging these strategies, industries can ensure that central valves operate within optimal parameters, thus maximizing flow efficiency while minimizing energy consumption.

Additionally, the adoption of smart monitoring systems has been pivotal in hydraulic valve performance, addressing the challenges of operational stability and efficiency. The use of sensor technologies enables real-time data collection and analysis, allowing for dynamic adjustments based on current operational conditions. For example, integrating AI for predictive maintenance in hydrogen fuel cells showcases the potential of such technologies. These innovations not only streamline workflows but also enhance overall performance, enabling systems to adapt swiftly to varying demands, which is essential in contexts like renewable energy systems, where fluid control is vital for optimizing system interactions and energy output.

Performance Testing: Evaluating Central Valves against ANSI/ISA and ISO Standards

In optimizing fluid flow efficiency with central valves, it's essential to rigorously evaluate their performance against established industry standards. The ANSI/ISA and ISO standards serve as critical benchmarks that ensure central valves operate effectively within their intended applications. By adhering to these standards, organizations can significantly enhance the reliability and safety of their automation systems, contributing to smoother workflow processes across various industries.

Performance testing involves a comprehensive analysis of central valves to assess their compliance with these standards. This includes evaluating factors such as flow capacity, response times, and operational reliability under various conditions. By conducting thorough performance evaluations against ANSI/ISA and ISO criteria, businesses not only maximize efficiency but also minimize risks associated with fluid handling in automated environments. Emphasizing standardization in testing procedures allows organizations to streamline their operations, thereby reinforcing their commitment to safety and efficiency in automation practices.

Case Studies: Real-World Applications of Central Valves in Improving Fluid Dynamics Efficiency

Central valves play a pivotal role in enhancing fluid flow efficiency across various industries, as demonstrated by multiple case studies. In the oil and gas sector, for instance, the implementation of advanced central valves significantly streamlined the extraction process. By reducing backpressure and minimizing turbulence, these valves not only helped in conserving energy but also improved the overall throughput of the system. This case illustrates how precise valve control can lead to substantial operational cost savings while meeting industry standards for safety and performance.

Another compelling example is seen in water treatment facilities, where central valves are employed to manage flow rates effectively. A recent upgrade to these systems has shown a remarkable decrease in energy consumption by optimizing the flow path and reducing friction losses. Facilities that embraced modern valve technology experienced enhanced filtration efficiency, resulting in higher quality water output and reduced chemical usage. By aligning with industry standards, these implementations not only improve fluid dynamics but also contribute to sustainability goals.

Related Posts

-

Maximize Your Global Reach with Central Valves at the Record Breaking 2025 Canton Fair

-

Understanding Industry Standards: How to Choose the Best Back Valve for Optimal Performance

-

Finding Top Suppliers for Best Valve Models with Industry Insights and Data

-

Ultimate Checklist for Choosing the Right Automatic Valves for Your Industrial Needs

-

How to Select the Right Valve Control Valve for Your Industrial Application

-

Comprehensive Solutions for Optimizing Hydraulic Pressure Control Valve Performance