Ultimate Guide to Selecting the Right Automated Valves for Your Industry

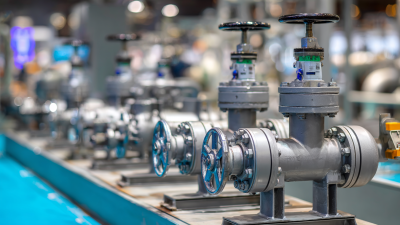

In today's rapidly evolving industrial landscape, the selection of the right equipment is crucial for operational efficiency and reliability. Among these critical components, Automated Valves stand out for their ability to enhance system performance while minimizing human intervention. This comprehensive guide will delve into the myriad benefits of incorporating Automated Valves into various industries, highlighting their role in optimizing processes, improving safety, and reducing costs. From manufacturing to water treatment, the advantages of these intelligent devices are far-reaching, making them an indispensable choice for modern operations. Whether you are considering upgrading your current systems or implementing new technologies, understanding the benefits of Automated Valves is essential for making informed decisions that align with your industry's unique needs.

Understanding the Different Types of Automated Valves Used Across Industries

When selecting automated valves for your industry, it’s essential to understand the various types available and their specific applications. Automated valves, which are integral to controlling flow in processes, can be categorized into several types including ball valves, gate valves, globe valves, and butterfly valves. According to a recent report by MarketsandMarkets, the global market for automated valves is projected to reach USD 10 billion by 2025, growing at a CAGR of 6.1% from 2020. This growth reflects the increasing demand for automation in industries such as oil and gas, water and wastewater, and chemical manufacturing.

Ball valves are prized for their ability to provide a tight seal and quick shut-off, making them ideal for applications that require on/off control. In contrast, globe valves offer precise throttling capabilities, which makes them suitable for flow regulation in processing plants. Additionally, the report highlights that the water and wastewater management sector is expected to witness significant investments, prompting an increased focus on automated valve solutions that enhance efficiency and reliability. Understanding these types allows industries to make informed decisions when implementing automated systems, streamlining operations, and maximizing productivity.

Ultimate Guide to Selecting the Right Automated Valves for Your Industry

| Valve Type | Application | Advantages | Materials | Common Industries |

|---|---|---|---|---|

| Ball Valve | On/off control | Low pressure drop, quick operation | Stainless Steel, Brass, PVC | Oil & Gas, Water Treatment |

| Globe Valve | Flow regulation | Good throttling ability | Cast Iron, Stainless Steel | Chemical, Power Generation |

| Butterfly Valve | Flow control | Lightweight, quick operation | PVC, Ductile Iron, Stainless Steel | Water Supply, HVAC Systems |

| Solenoid Valve | Automated control | Fast actuation, compact | Brass, Stainless Steel, Plastic | Manufacturing, Automation |

| Check Valve | Prevent backflow | Automatic operation | Cast Iron, PVC, Stainless Steel | Water Treatment, Oil & Gas |

Key Factors to Consider When Selecting Automated Valves for Specific Applications

When selecting automated valves for specific applications, it’s essential to consider key factors that impact performance and efficiency. According to a report by the Valve Manufacturers Association, a staggering 40% of industrial valve failures can be attributed to incorrect specifications. Factors such as pressure and temperature ratings, flow characteristics, and valve material compatibility should be carefully assessed. For instance, in the oil and gas industry, using valves that can withstand corrosive media and high pressures is crucial for ensuring safety and operational integrity.

Tip: Always consult with manufacturers about the specific conditions your automated valves will face to ensure they meet industry standards and requirements.

Another critical consideration is the control mechanism of the automated valve. With the rise of Industry 4.0, smart valves equipped with IoT capabilities are increasingly favored for their ability to provide real-time monitoring and predictive maintenance features. A study from the International Society of Automation highlighted that companies adopting smart valve technology could reduce maintenance costs by up to 30% while improving overall system efficiency.

Tip: Evaluate the integration capabilities of automated valves with existing systems to maximize their functionality and performance.

Analyzing Industry Standards and Regulatory Compliance for Valve Selection

When selecting automated valves for industrial applications, adhering to industry standards and regulatory compliance is crucial. Proper compliance ensures not only safety but also operational efficiency. Each sector, whether it be pharmaceuticals, chemical processing, or food production, presents its own set of standards that dictate the types of materials and designs required for valve selection. For instance, valves must often meet specifications such as ANSI, ISO, or API standards to facilitate proper functioning under various pressure and temperature conditions.

The PTFE-lined plug valve market exemplifies the importance of these considerations, with projected growth from $64.14 million in 2024 to $84.01 million by 2032, reflecting an annual growth rate of 3.4%. This growth can be attributed to the increasing demand for valves that provide enhanced chemical resistance and reliability in critical applications. As industries continue to innovate, the need for compliance with regulatory bodies that oversee safety and environmental impact will shape the evolution of valve technology, driving manufacturers to prioritize the development of products that meet these stringent requirements.

Evaluating the Impact of Valve Material and Design on Performance and Longevity

When selecting automated valves for your industry, understanding the impact of valve material and design on performance and longevity is crucial. Research indicates that materials like stainless steel and high-performance plastics can enhance valve lifespan by up to 30% in corrosive environments. For instance, a study published by the Valve Manufacturers Association highlights that valves made from abrasion-resistant alloys significantly reduce wear and increase reliability, ultimately leading to lower maintenance costs and downtime.

**Tip 1:** Always consider the environmental conditions where the valves will be used. Factors such as temperature, pressure, and exposure to chemicals can drastically affect the material selection process.

The design of automated valves also plays a fundamental role in their operational efficiency. Streamlined designs can minimize pressure drops and optimize flow rates, resulting in better energy efficiency. According to a technical report by the International Society of Automation, adopting advanced valve designs can improve process efficiency by as much as 15%. This emphasizes the need for evaluating not just the materials but also the overall design specifications before making a selection.

**Tip 2:** Engage with suppliers who offer comprehensive data on valve performance metrics. This data can provide valuable insights that aid in choosing the right valve tailored to specific operational needs.

Cost-Benefit Analysis of Automated Valves: Investment vs. Operational Efficiency

When it comes to selecting automated valves for your industry, a thorough cost-benefit analysis is crucial. Studies show that investing in high-quality automated valves can lead to operational efficiency gains of up to 30%. This efficiency translates not only to reduced downtime but also to lower energy costs, as modern automated systems often utilize less energy than traditional manual valves. For instance, a report by the Valve Manufacturers Association indicates that industries utilizing automated valves experienced an overall decrease in maintenance costs by 25%, showcasing the long-term savings possible through initial investment.

**Tip:** Always assess the total cost of ownership (TCO) when evaluating automated valves. This includes not just the purchase price but also installation, maintenance, and energy usage over the valve's lifecycle.

Moreover, consider that automated valves contribute to better process control and higher safety standards. According to recent industry research, automated systems can reduce human error by 70%, ensuring safer working conditions and compliance with stringent regulatory requirements. This aspect makes automated valves not just an investment for cost savings, but a necessary step towards operational excellence.

**Tip:** Engage with manufacturers to obtain detailed performance data and case studies supporting the economic benefits of their products, which can facilitate informed decision-making.

Cost-Benefit Analysis of Automated Valves

This bar chart represents the investment cost and operational efficiency benefits of automated valves in various industries. The investment cost is measured in thousands of dollars, while operational efficiency is expressed as a percentage increase in productivity over traditional valves.

Related Posts

-

Evaluating Automated Valves: A Comparative Analysis of Performance Metrics and Efficiency in Industrial Applications

-

Essential Guide to Selecting Top Manufacturers: Solutions for Best At Control Valves Procurement

-

Solutions for Efficient Hyd Control Valve Implementations

-

The Ultimate Guide to Selecting the Best Control Hydraulic Systems for Your Global Procurement Needs

-

10 Best Elevator Valve Solutions for Global Buyers in 2023

-

Understanding Import Export Certifications for Best Pressure Valves with a Step by Step Guide